A B O U T U S

Stamperia di Lipomo

The family company has been working for more than 60 years in the textile industry and it is mainly focused on texile printing and finishing.

womenswear

menswear

kidswear

Accessori moda, bags, scarves, ties

swimwear

underwear

sportwear

technical

Interior design

Abbigliamento femminile,

womenswear

Accessori moda,

bags, scarves, ties

swimwear

underwear

sportswear

technical

O U R C L I E N T S

O U R

C L I E N T S

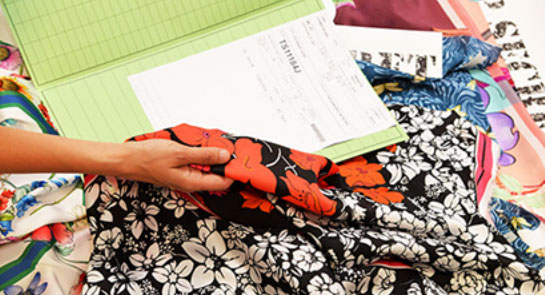

Converters and shops in fact rely on SdL for the best economic solution, quality and safety for the final product.

Due to our mid-dimension structure and in order to keep our production at a top level we do not address to private or shops directly.

W H A T W E D O

W H A T W E D O

We work with any kind of fibre

In order to get and offer the best quality for each kind of technique we employ vertical, complete and controlled cycles using handmade, traditional and digital print systems.

HANDMADE

PRINT

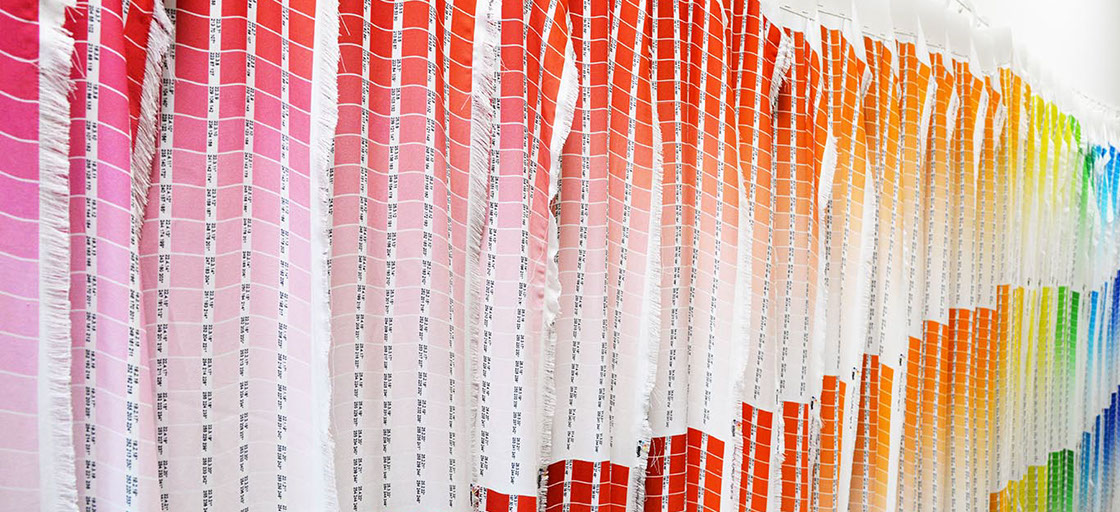

Among the three it is doubtless the most ancient. Together with the use of modern machinery it actually guarantees the best results on fabrics so that the final product shows a unique craftsmanship thanks to the brightness of the colours, its printing definition, its variety of shades and also with a touch of reinflate effects, metallic colours and lacquers.

What made Como famous all around the world is the use of such ancient techniques which have been coveyed throughout the ages.

TRADITIONAL

PRINT

The use of both the machine by hand and the ten-colour rotary machine converts the handmade product into an industrial one by preserving its essence and guaranteeing a great productivity at the same time.

DIGITAL

PRINT

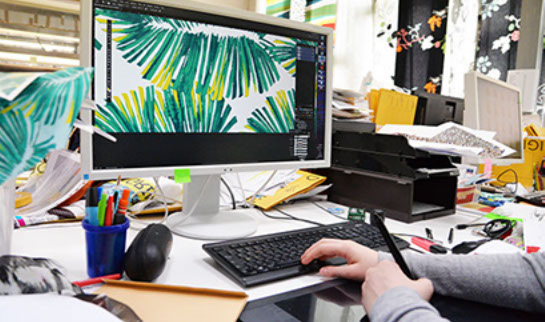

Last but not least, digital print is the most recent one: fantasy is the unique limit of ink jet.

Thanks to a close and dedicated team of people digital drawings are developed and it is possible to print them for a huge number of articles getting unexpected results.

We have been studying dedicated cycles for innovative fabrics and markets, together with the chance to print exact combinations of colours even much time later.

N O T O N L Y P R E S S

N O T O N L Y

P R E S S

Reliability of our products is possible by checking carefully both all the pre-treatments of printing preparation and all the post-treatments on fixing, washing and finishing processes. We can guarantee and offer strong and efficient cycles of production only by continuous research and dedication to our products and materials.

FIXING

WASHING

FINISHING

In the 1990s Giannino entrusted the management of the company to his three sons: Gianluca, Matteo and Marco. And since the beginning of the new millennium the SdL has enhanced its digital department turning it into the main and most productive unit in the SdL in few years.

S U S T A I N A B I L I T Y

An eco-friendly company

A company fully focused on Sustainability

The next challenge in textile will be being able to achieve a sustainable production.

Thanks to continuous innovation in machineries with better energy performances coupled with the use of renewable resources we were able to make energy and resources consumption one of our goal.

We have a photovoltaic system that generates 569 KW/h; which allows us to be self-sufficiently in some periods of the year and it statistically covers about one third of our internal consumption of energy. We estimate to not release 170 tons of CO2 per year into the atmosphere.

The concept of Sustainability has always been connected to chemical substances management , where we are commitment to research new formulations with a lower toxicity impact on the planet. Daily researches and replacement of chemical formulations allow us to print in a sustainable way and be able to provide a safe and reliable product to our customers.

La Stamperia is registered on the ZDHC Gateway portal and began the Supplier to Zero process. We were able to certify the mill as: ZDHC Foundational.

We obtained the certification FOR TEXTILE, specifically created by companies in our local production district to declare to our costumers: chemicals used in production, MRSL, PRSL guidelines and high Eco-toxicological level that we ensure.

This certification comes along with SA8000 and ISO14001.

We achieved GRS certification in 2020 for the following fibers: polyester, polyamide, cotton, elastane, silk, cashmere, polyurethane and in 2023 we received it for sales too. In February 2024 we achieved GOTS certification both as subcontractors and sellers. The certifications we obtained, those we aim to achieve in the very next future and the investments that the company did and will continue doing on modern machineries (with a green purpose), enhance the company’s commitment to ESG pillars and the sustainable growth that the Company has decided to pursue and constantly improve over the future years. In 2022 Stamperia di Lipomo achieved Iso9001 certification to ensure to costumers an high level of quality.

Area Download Certifications and Documents

CERTIFICAZIONE GRS

ISO 9001: 2015

GOTS

FOR TEXTILE

ZDHC FOUNDATIONAL

C O L L E C T I O N

O U R

C O L L E C T I O N

Top Secret

V I D E O

Welcome MonnaLisa

The first industrial printer

for digital textile printing.

The first industrial printer

for digital textile printing.

WOODEN PALLET

PALLET

FOR 50

WOOD

97/129/EC: Commission Decision of 28 January 1997

SEPARATE COLLECTION

Check with your Municipality how to dispose of this packaging

CELLOPHANE

STRETCH FILM

PE-LD 4

LOW DENSITY POLYETHYLENE

97/129/EC: Commission Decision of 28 January 1997

PLASTIC WASTE COLLECTION

Check with your Municipality how to dispose of this packaging

ADHESIVE TAPES

ADHESIVE TAPES

PP 5, PVC 3

POLYPROPYLENE AND POLYVINYL CHLORIDE

97/129/EC: Commission Decision of 28 January 1997

PLASTIC WASTE COLLECTION

Check with your Municipality how to dispose of this packaging

ADHESIVE TAPES in PAPER and in POLYETHYLENE

ADHESIVE TAPES

PAP 22, PE-LD 4

PAPER and LOW DENSITY POLYETHYLENE

97/129/EC: Commission Decision of 28 January 1997

UNDIFFERENTIATED COLLECTION

PAPER TUBES

TUBE

PAP 21

NON-CORRUGATED CARDBOARD

97/129/EC: Commission Decision of 28 January 1997

PAPER WASTE COLLECTION

Check with your Municipality how to dispose of this packaging

STRETCH FILM

STRETCH FILM

LDPE 4

Polyethylene LDPE

97/129/EC: Commission Decision of 28 January 1997

SEPARATE COLLECTION

Check with your Municipality how to dispose of this packaging

Stamperia di Lipomo SpA

Via Provinciale, 219 – 22030 Lipomo (Como)

Tel. +39 031.5591 – Fax +39 031.559226

da lunedì a venerdì dalle 8.00 alle 12.30 – dalle 13.30 alle 18.00

info@stamperiadilipomo.com

Cap. Soc. 2.100.000,00 iv – R.E.A. Como n. 88990 – P.I. e C.F. IT 00627510134